Rhino 3D Design Software

Powerful 3D modelling software for designers, engineers and architects.

Rhino can create, edit, analyse, document, render, animate and translate NURBS curves, surfaces, solids, point clouds and polygon meshes. Rhino has been designed to remove as many workflow bottlenecks as possible, making it fast and able to handle large models and project teams.

Enjoy uninhibited free-form 3D modelling tools to model any shape you can imagine with all the accuracy you need to produce prototypes and designs for manufacture for anything from a wedding ring to an aircraft.

Marine Design

Through Rhino, marine designers can translate their visions into precise 3D models, allowing effective communication with shipbuilders, engineers, and stakeholders.

Architecture

Rhino is uniquely capable in the architectural space. Its precision, handling of complex forms and procedural modelling from Grasshopper make it an essential architect’s tool.

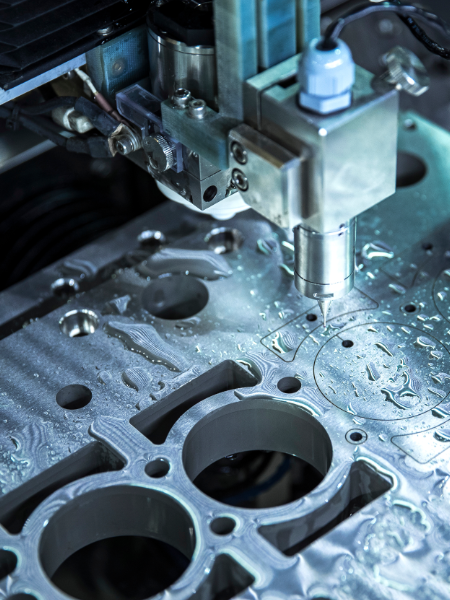

Engineering & CADCAM

Precision modelling and powerful CAM plugins make Rhino an ideal platform for engineering and CNC manufacturing.

Landscape Design

Coupled with plugins like Lands Design, Rhino 3D is an easy to use, powerful modeller for landscape and urban design.

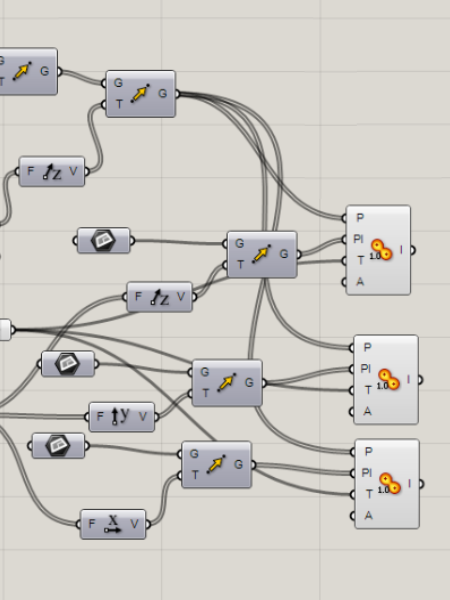

Computational Design

With Rhino’s powerful modelling features available for programmable interaction through Grasshopper, it’s possible to do things with Rhino that are impossible with other modellers.

Jewellery Design

Precision and lightweight geometry make Rhino perfect for jewellery design. With specific jewellery and rendering plugins, Rhino is the perfect workflow.

Product & Industrial Design

Few applications handle complex forms and surfaces as well as Rhino 3D – making it the ideal platform for industrial and product designers.